Description

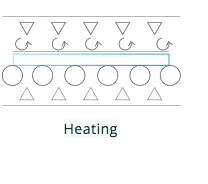

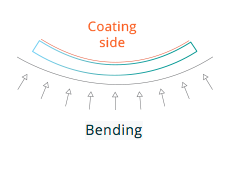

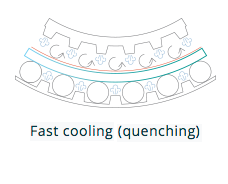

Curved toughened glass, also known as tempered glass, is manufactured using a fast heating and quenching process. The glass is heated up to 600ºC, curved by oven rollers, and then quenched or cooled rapidly.

This process introduces stresses in the glass, improving its overall material strength.

While not as versatile as annealed curved glass, toughened glass employs a faster production process and enables the use of the best Energy Efficient coatings such as Low-E and High Selectivity coatings. Heat strengthened glass is very similar and produced in the same oven, but quenched more slowly.

General Details

• Fast bending process of approximately 15 minutes

• Almost all coatings can be applied

• High security and safety interlayers available

• Breakage is safer, it occurs in small parts with blunt edges

• Anisotropy and roller wave distortions must be taken into account and are inherent to the process

• Coloured interlayers are not advisable

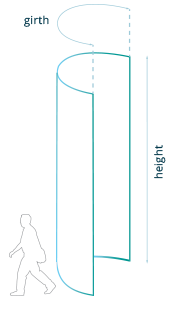

DIMENSIONS, OVEN 1: 2440 X 4500 mm / 96” X 177”

DIMENSIONS, OVEN 2: 4200 X 3200 mm / 165” X 126”

DIMENSIONS, OVEN 3: 1500 X 3200 mm / 59” X 126”

(For larger dimensions, please contact us )