Description

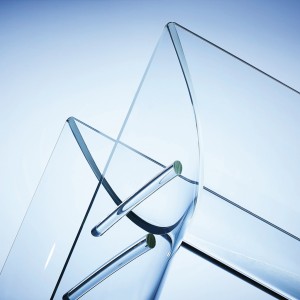

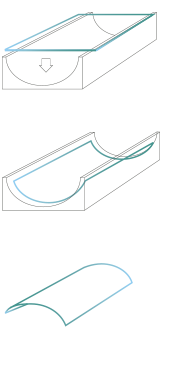

Curved annealed glass is manufactured by slowly heating flat glass up to the softening temperature, around 550ºC, when the glass starts slumping due to gravity on the customized mould.

Once the desired geometry has been achieved, the glass is slowly cooled. Known as “annealing”, this key phase determines the visual quality and structural properties of the final product.

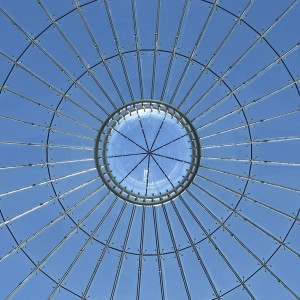

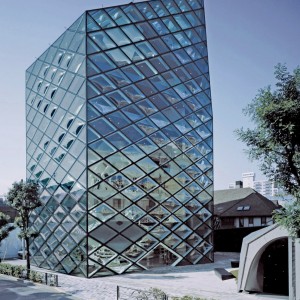

Annealed glass is versatile and allows for a vast range of shapes, textures and forms in architecture.

Manufacturing process of

annealed curved glass.

General Details

• Slow bending process, approximately 5 – 8 hours

• High optical quality

• Wide range of coatings are suitable

• Ceramic frits can be used

• Coloured and printed PVB options

• High security and safety interlayers available

• Breaks in large parts, with post-breakage structural behaviour when laminated

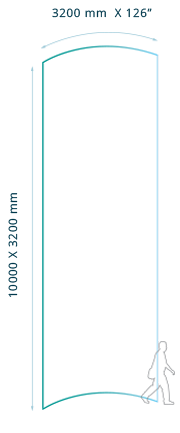

DIMENSIONS: 10000 X 3200 mm / 394” X 126”

(For larger dimensions, please contact us )

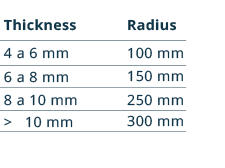

Minimum radii according to glass thickness