Nike动态幕墙 / Looking through the rippled glass

©CRICURSA |

|

An exemplary project where fabrication possibilities and engineering are celebrated in architectural design.

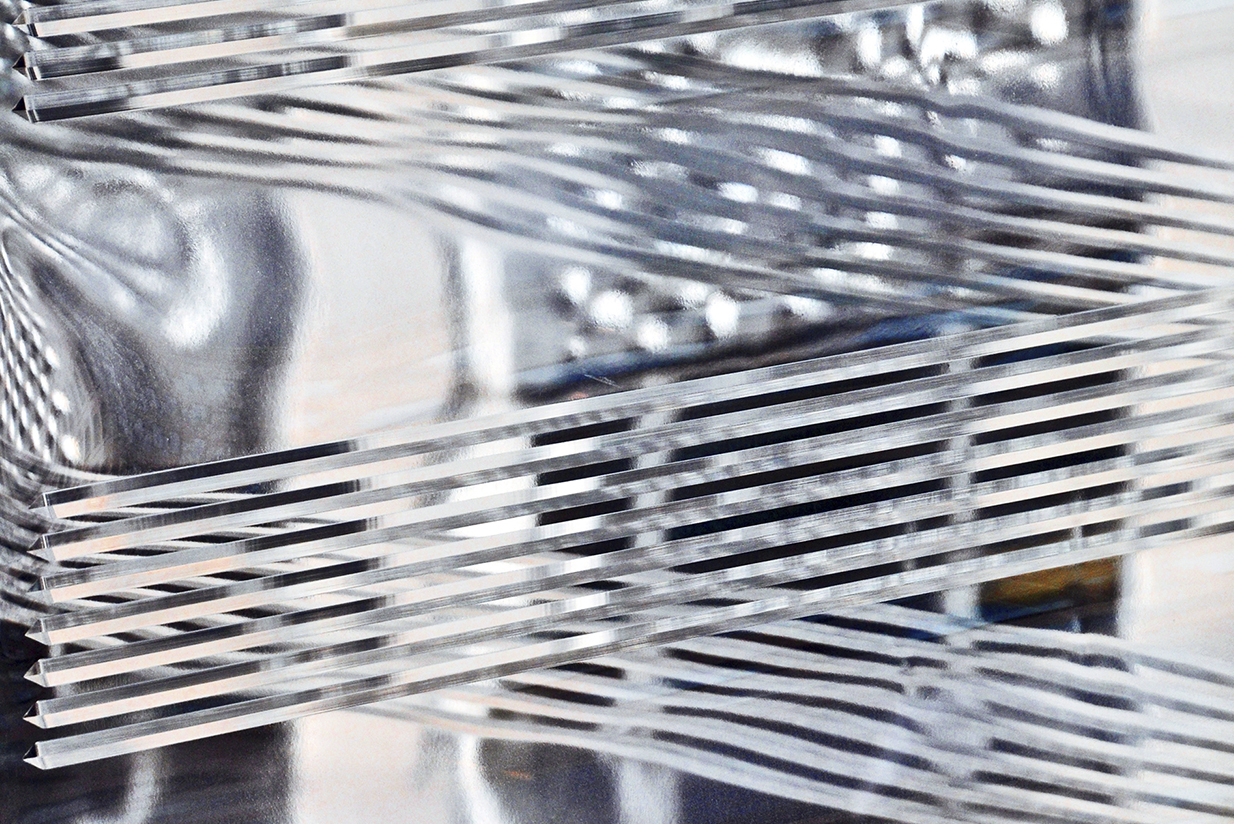

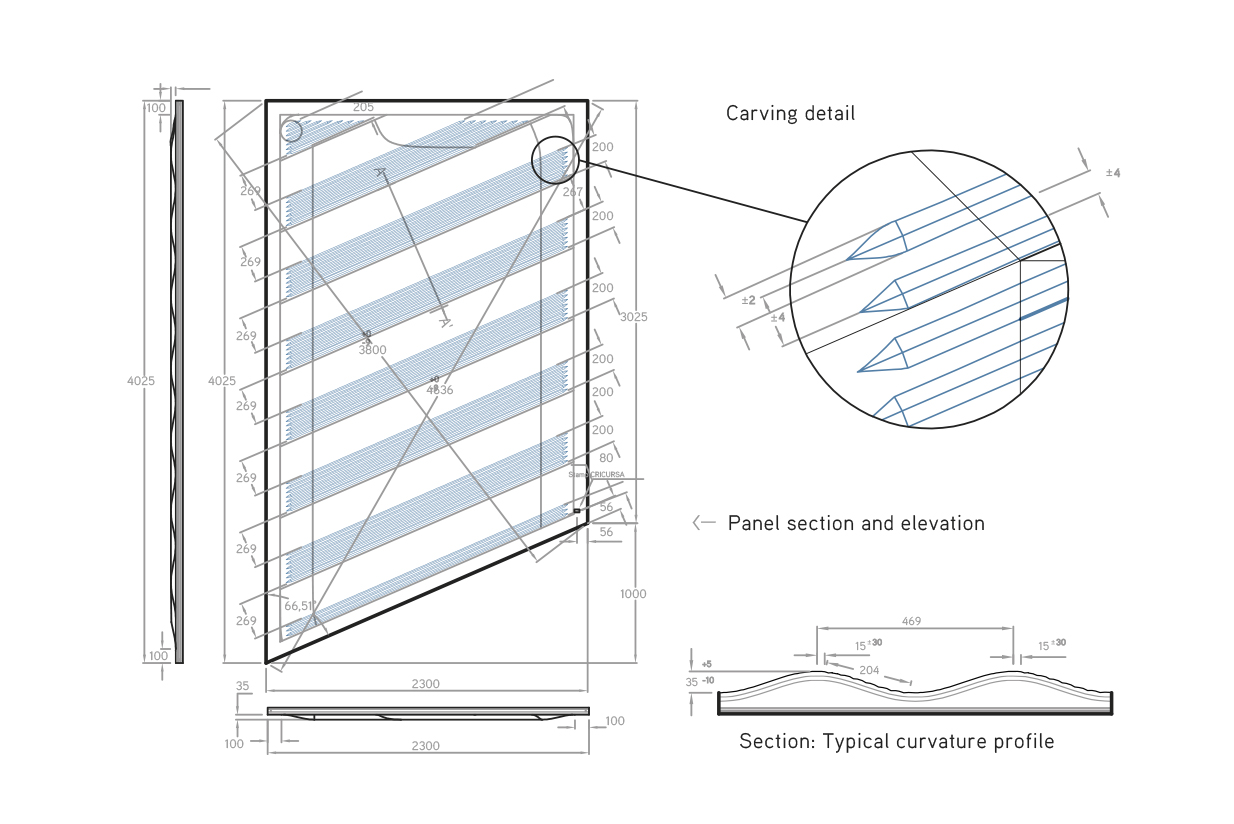

©CRICURSA CRICURSA developed a sustainable solution to limit the number of unique slump moulds – which take up a significant amount of space, material and time – and regularized the module into a single sized rectangular panel. Only three additional moulds were crafted to fabricate irregular shapes framing the entrance. The process of milling the surface was done at high speed with the glass laying flat in a CNC polishing station. A complex operation with 115 linear meters of carved lines per panel and a risk of breakage at any time. The grooves were created with various tooling, using 20mm wide millstones (168°) getting 1.05mm deep.

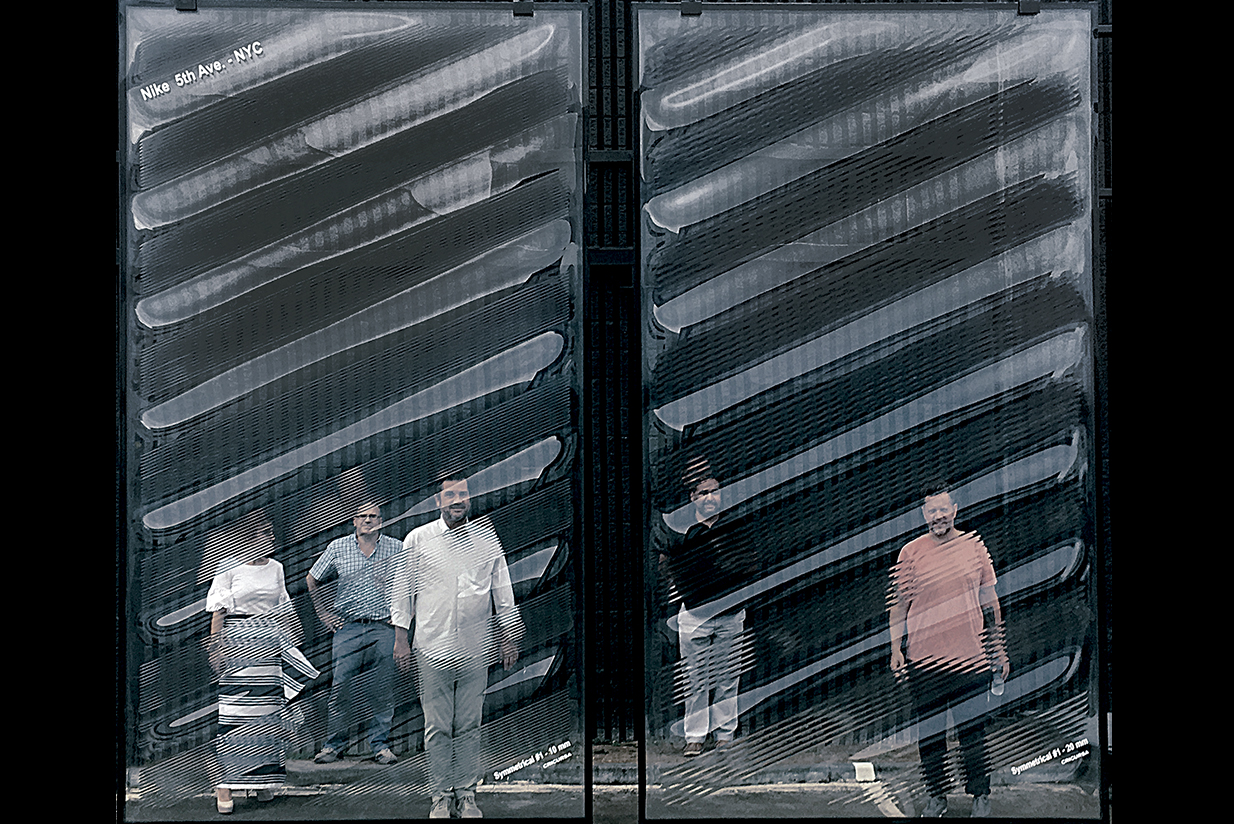

©CRICURSA, Heintges CRICURSA created full-size samples approximately 2350mm wide by 4090mm high for review by Nike, CallisonRTKL and Heintges to confirm the final design for the micro-pattern and macro-pattern. Full-size performance testing conducted by Heintges tested five samples to their ultimate load capacity including differential thermal loading, wind pressure loading, and structural loading to an effective safety factor of four times the design load.

©Heintges The result is a powerful architectural statement, a glass curtain with its own regular modulation in front of the variously spaced floor slabs enclosed behind.

©CRICURSA |

|

|